Metal Matters

Shell Bodies of the First World War

When first I heard the phrase “steel on target,” it struck me as odd. After all, I thought, the delivery of metal containers by means of cannon was merely a means to the end of conveying suitably-fuzed explosive material. Indeed, it was only until I began to learn about the various kinds of shells fired during the First World War that I came to appreciate the connection between the metal used to make a shell and the payload it carries.

The best description of this relationship I have yet to find appeared in a set of class notes written for the use of students at the Military Artillery School [École Militaire d’Artillerie] of the French Army. Published in December of 1919, this little book compared three projectiles fired by the 155mm de Bange gun (Model 1877) during the World War:

a cast iron shell adopted in 1877

a semi-steel shell adopted in 19151

a steel shell adopted in 1914

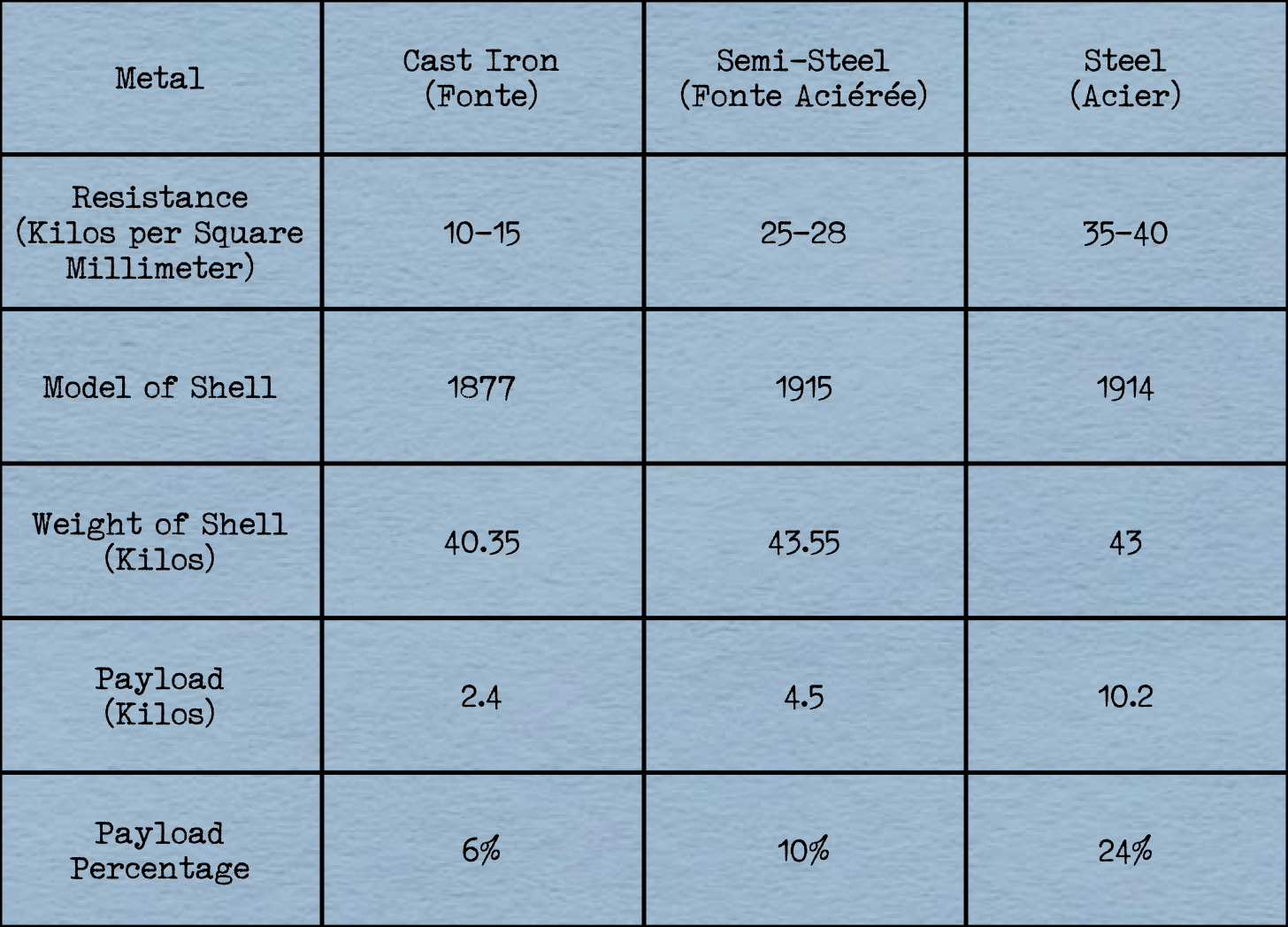

The author of the class notes, Captain Gomès, explained the strength of the three metals by giving figures for their ability to resist pressure. While cast iron could only resist pressures that ranged between 10 and 15 kilos per square millimeter, steel was able to withstand forces were more than three times as great. Semi-steel, which occupied the middle ground between cast iron and pukka steel, could handle pressures of 25 to 28 kilos per square kilometer.

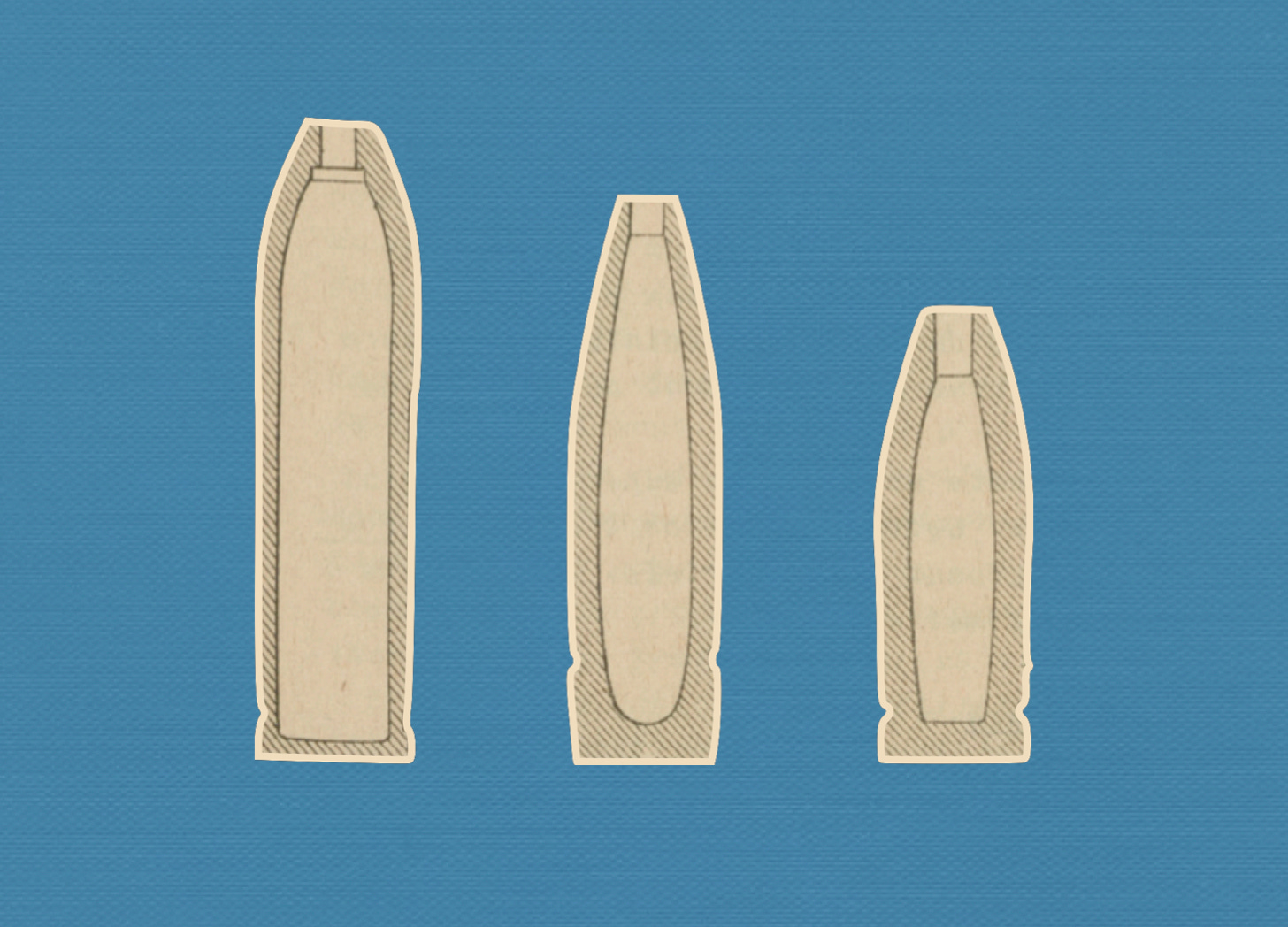

To illustrate the implications of the differences in resistance, Captain Gomès provided a picture that compared cross sections of the three shells. This drawing made it clear that the projectile made out of steel had noticeably thinner walls than shells made out of other materials. Moreover, while a little lighter than the semi-steel shell, it was much longer than either of its counterparts, to the point where it earned the designation of “elongated shell” [obus allongé].

Strange to say, Captain Gomès declined to mention the effect that the thickness of the walls of an artillery shell had on its payload. Figures for that phenomenon, however, can be found in a catalogue of artillery pieces and ammunition published in 1918.2 These show that a steel shell designed for use with a 155mm gun could carry more than twice as much explosive than a corresponding semi-steel shell. The latter, in turn, could deliver a charge that was almost two times as large as that conveyed by a cast iron shell.

For Further Reading:

To Share, Subscribe, or Support:

While not as strong as steel, semi-steel (fonte aciérée) was both easier to make and form into shells than fully-fledged steel. During the first winter of the war, when steel was in short supply and the factories able to work it efficiently were fully occupied with the making of shells for 75mm guns, the French War Ministry authorized its use to make projectiles for heavy guns and howitzers.

Renseignements sur les matériels d'artillerie de tous calibres en service sur les champs de bataille des armées françaises [Information about Artillery Matériel of all Calibers Serving with French Armies on the Battlefield] (Paris: Imprimerie Nationale, 1918)

25 to 28 kilos per square kilometre? That ain't much pressure at all. 😊