If you have not done so already, please read the first two posts in this series.

Untimely Explosions (Background) will provide you with a short biography of the protagonist. Untimely Explosions (First Problem) describes the first problem faced by General Baquet.

Solution to the First Problem

You decide that you are far too busy with the task of acquiring ordnance to focus on the problem of premature explosions. You therefore ask a senior subordinate, Fernand-François Gossot, to conduct a detailed inquiry into the problem.

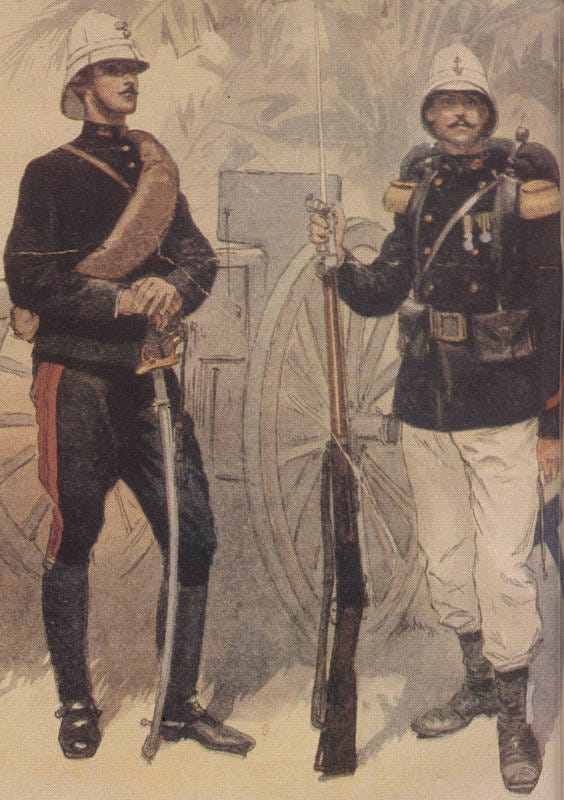

Brigadier General Gossot, who holds a masters degree in mathematics, has made a number of important discoveries related to interior ballistics. When not teaching mathematics at the École Polytechnique or conducting experiments in ballistics, he has commanded artillery units of the Troupes de la Marine and supervised the manufacture of naval ordnance.

The Second Problem

It is now 20 January 1915.

At present, French factories are producing, each day, 63,000 explosive shells for 75mm field guns. Of these, 22,500 shells are made by experienced factories, 40,500 by new factories.

Earlier today, General Gossot provided you an interim report of his findings. These are:

Between 2 August 1914 and 20 December 1914, 75mm field guns of the French Army fired 3,000,000 explosive shells. Of these projectiles, six exploded before leaving the barrel of the gun that fired them. Thus, for every 500,000 explosive shells fired, one exploded prematurely.

On 20 December 1914, batteries at the front began to take delivery of explosive shells made by new factories.

Since 20 December 1914, the rate of premature explosions has increased from one in 500,000 to one in 5,000.

General Baquet, what is going on here? What is your plan?

For Further Reading:

What's going on is shell production has skyrocketed because the guns must be fed, and quality control has gone to hell. My plan is I ask the question: what wins us the war?

Sadly, I think that what we need most to win the war is for the factories to be producing 150,000 shells per day rather than 60,000. Health and safety at work is a distinctly secondary concern when we're losing 25k men/week (my rough calculation of total French casualties over the war - my numbers at the time of the scenario may have been different but not substantially I bet) to enemy action.

Production must increase, and as far as possible so must the quality of what is produced. In the immediate term it's easy to say what we must do: put out more contracts for shell manufacture, go to the longstanding firms and (literally if necessary) dragoon their top men into working at the new factories to improve overall quality. If the quality of legacy factories deteriorates but we can get that 1/5k down to 1/20k while also improving production, that's an awful lot more dead Germans.

Looking to the long term, I propose that a new Office for the Supervision and Improvement of Quality in the Manufacture of Munitions be created reporting directly to me (or that whatever exists already in that regard be significantly expanded, in manpower and legal powers). I also propose that all chemical and manufacturing engineers in France not presently employed in essential war industries, and all students pursuing courses of study in the same fields, be declared liable for conscription but ineligible to serve other than in that office without extraordinary permission from me or M. le Général Joffre.

Still, I'm going to take the shells from the new ordnance companies and keep them separated from the general use. They will be used on if necessary, and will be marked as potential danger.